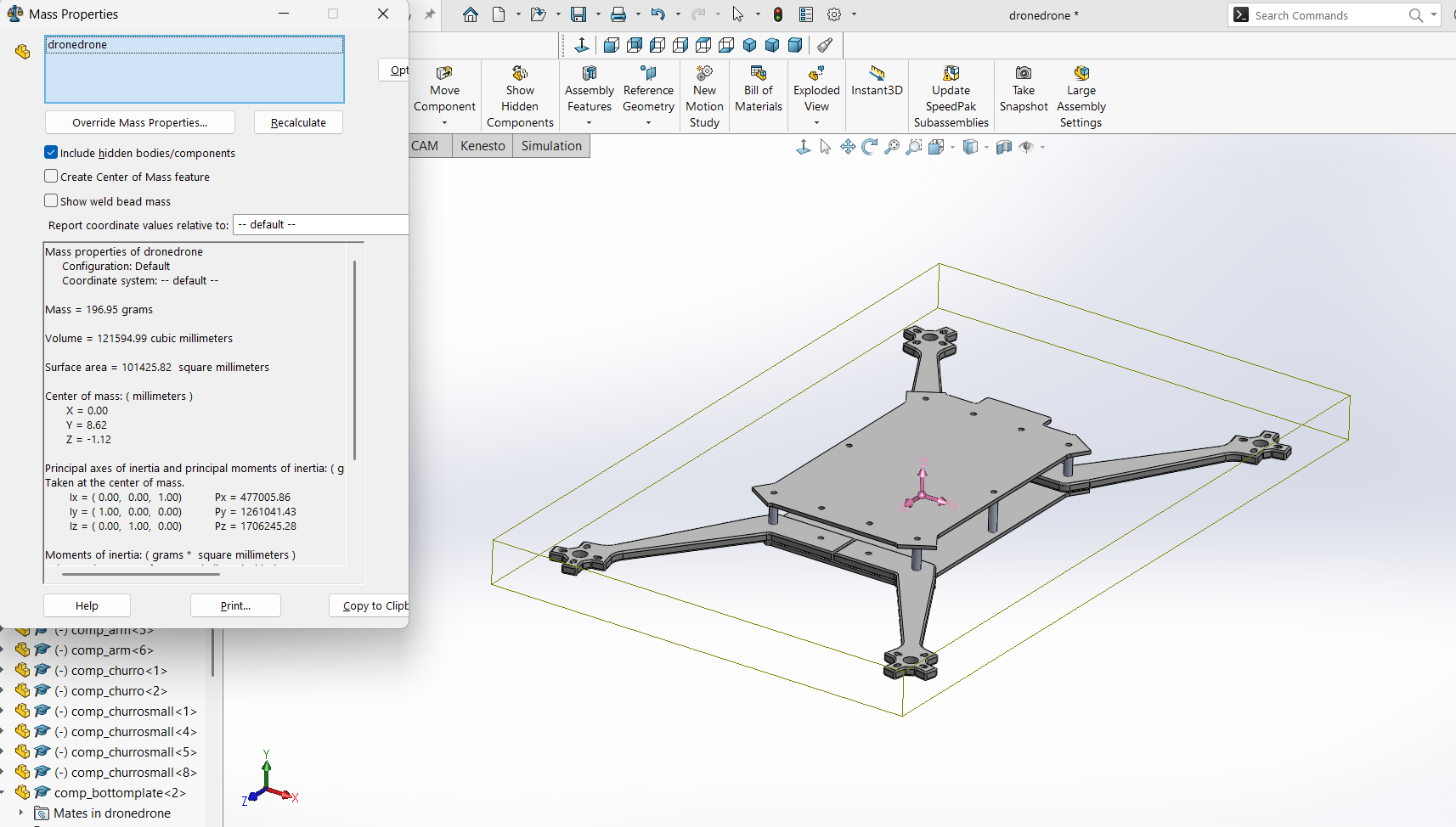

Custom Frame of the UAV

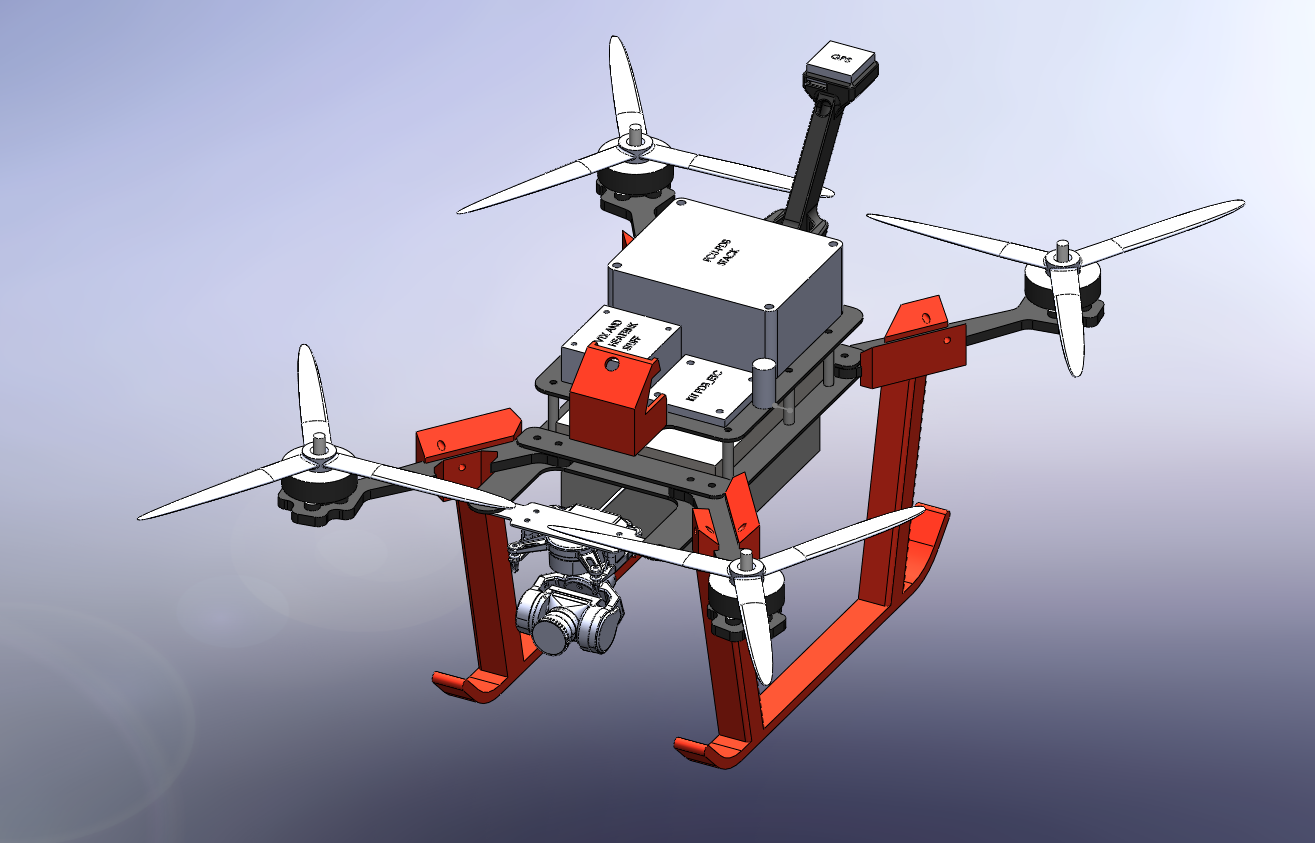

Designed a lightweight UAV (150.7 g, and 2kg total mass) that carries a dummy mass to scout terrain, assist rover navigation, and scan mission markers.

Mission will be held in 2026, at the University Rover Challenge in Utah.

Design constraints were created to follow our mission requirements, including:

- Minimizing mass while meeting flight-time targets

- Ensuring straightforward manufacturing

- Reliable assembly around custom onboard electronics

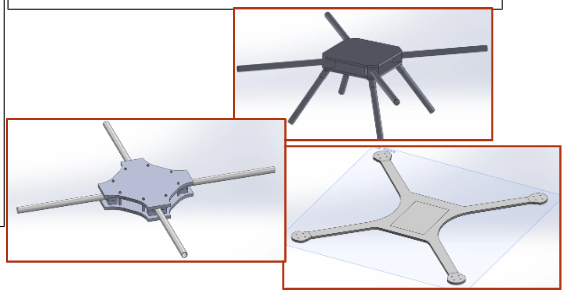

Started off with multiple design concepts.

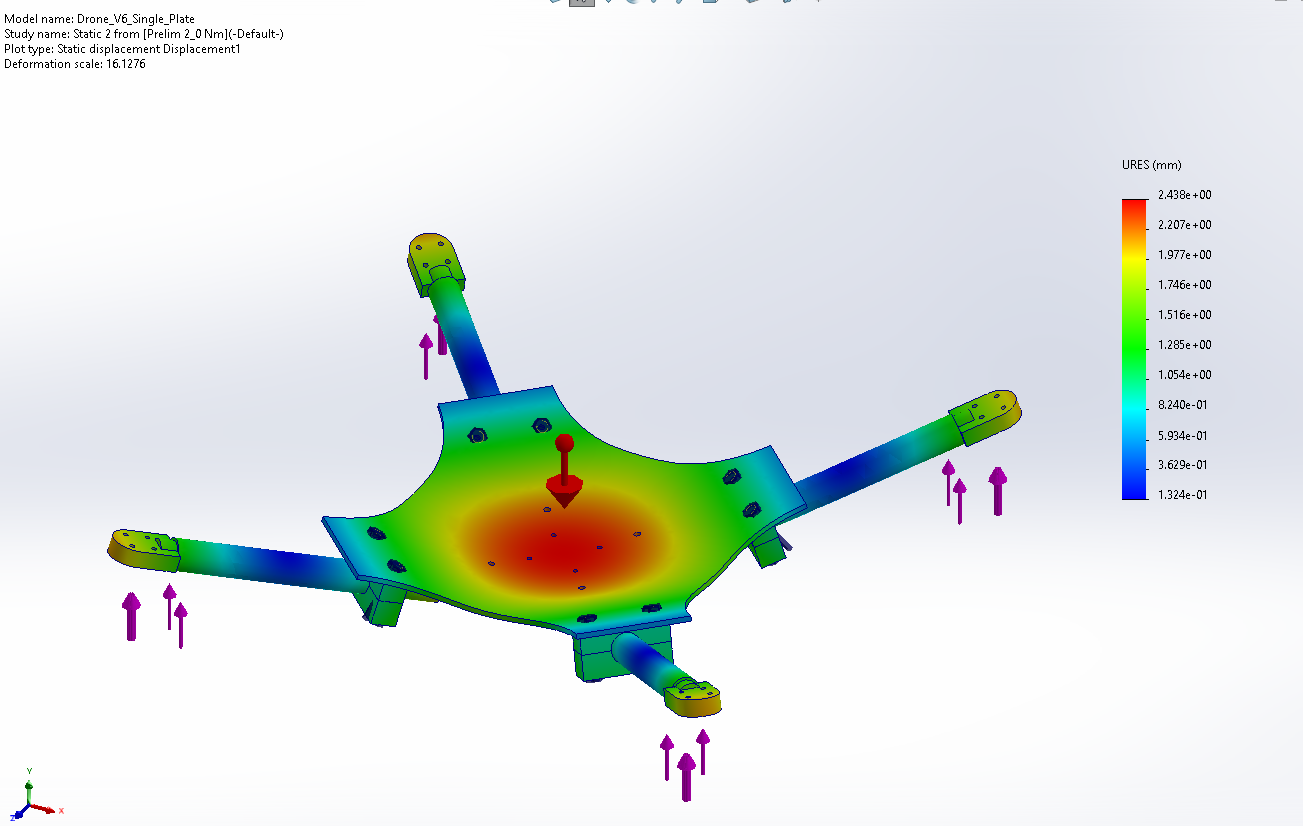

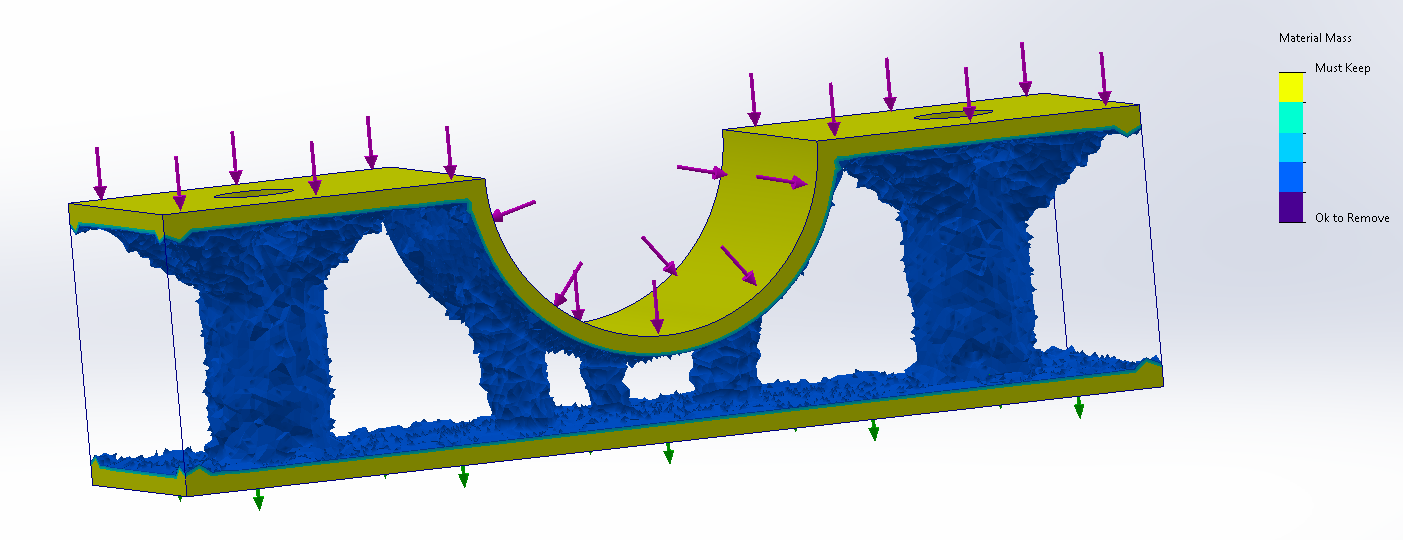

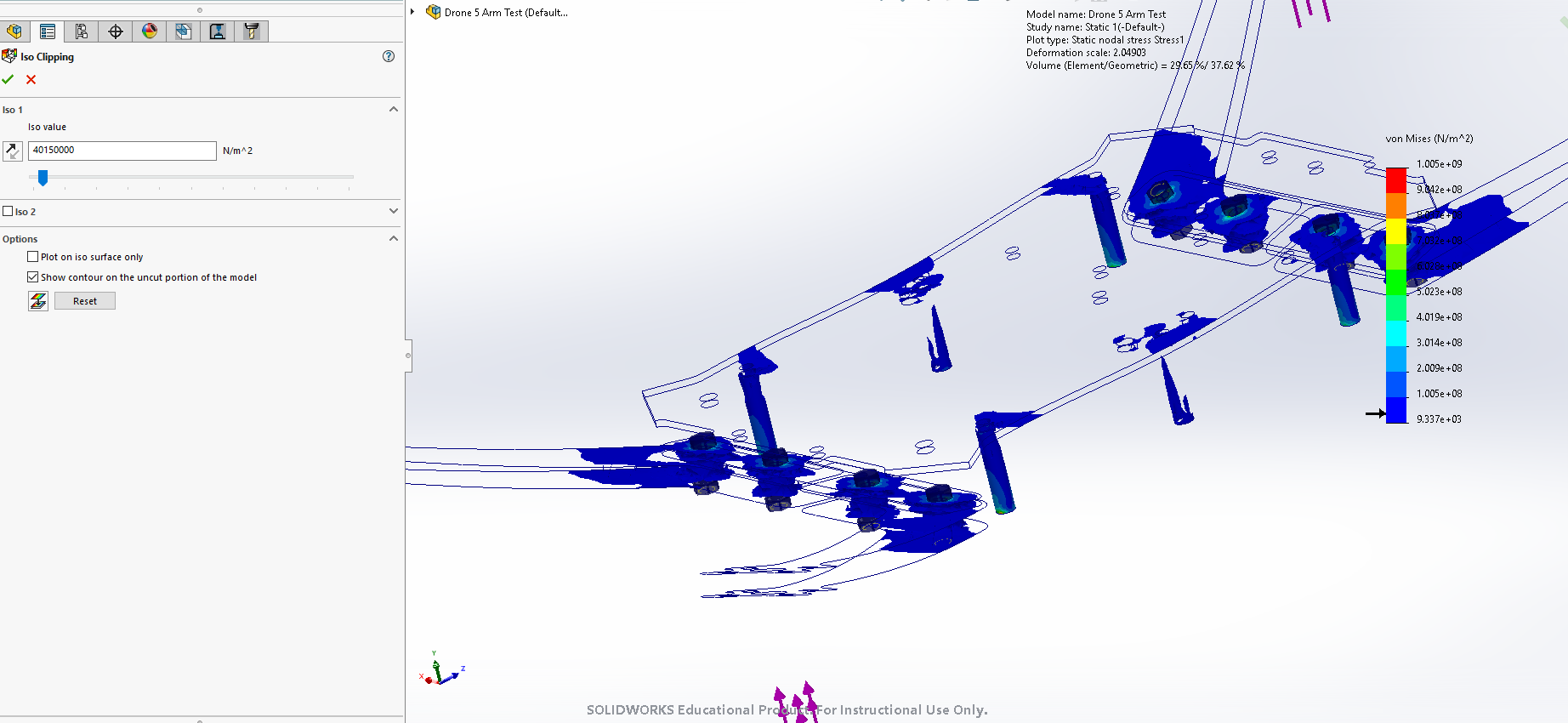

Lots of research into carbon-fiber material behaviour, SolidWorks simulations, and CAD developments were made.

Presented to professors, and got feedback from industry professionals. Applied it.

Tested multiple designs on SolidWorks.

A final design was finalized into the first full prototype (REV 1).

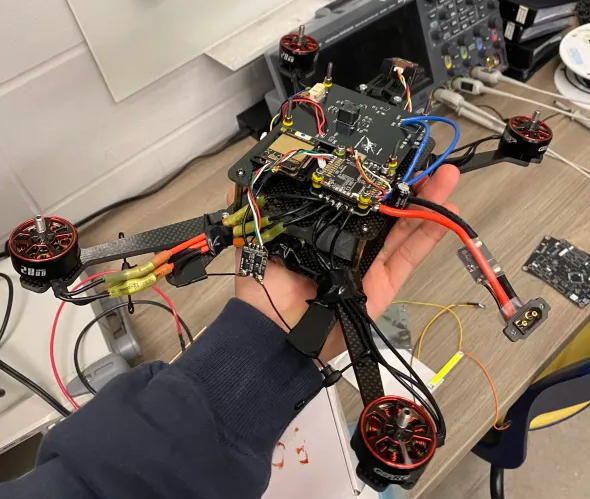

Finally go to testing. How’d it go?

We met our weight goals, and after some stable hovering and tuning, the frame my friend and I created held up!

There is still lots of testing and improvements to be done and get this drone ready for our competition.

I've learned a lot on how important core engineering practices are, including feedback-driven iteration, documentation, and following requirements.

(images of me flying some drones)